OEM: Product Design

Product functionality and DFM analysis

- Part information

- Mass distribution

- Weight optimization

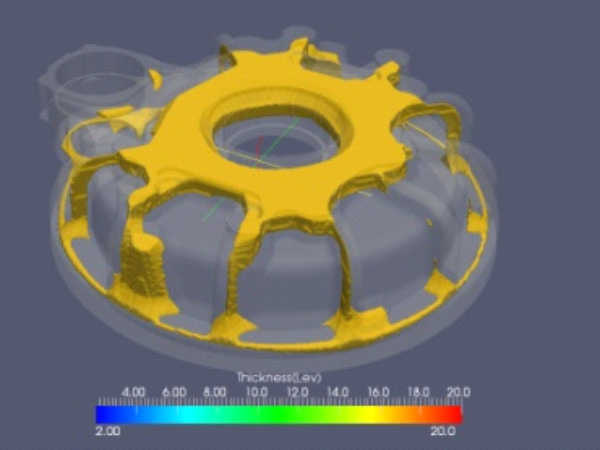

- Wall thickness (2D & 3D)

- Material cost

- Manufacturing cost

- Quick validation for new design

Synchronous Design

Co-design / Synchronous design between OEM and part supplier

- Detail part information

- Critical points of product

- Fast defects predict

- Quick / Immediately quotation base on difficult level of manufacturing

Manufacturing Design

Get real-time information for manufacturing process design

- Very detail part information and difficult level analysis

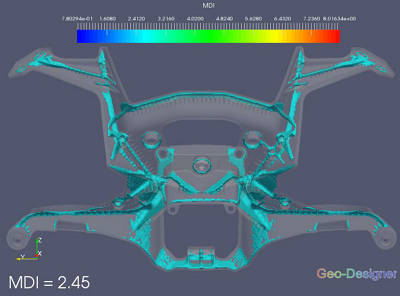

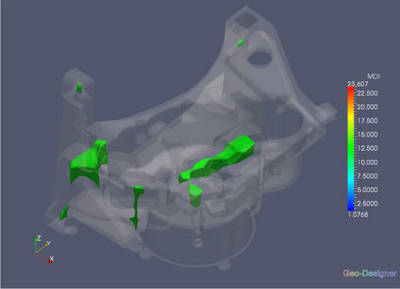

- Mass Distribution Index (MDI)

- Heat Distribution Index (HDI)

- Hot spots prediction

- Riser design

- Part optimization

- Quick quotation for part

Key Features

- Mass Distribution Index (MDI)

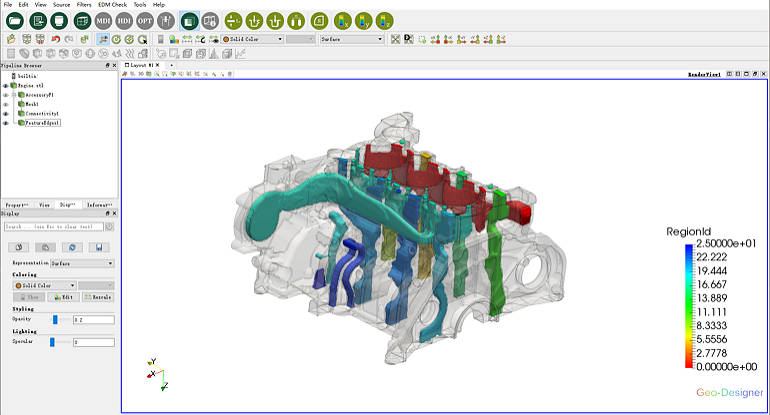

- Heat Distribution Index (HDI)

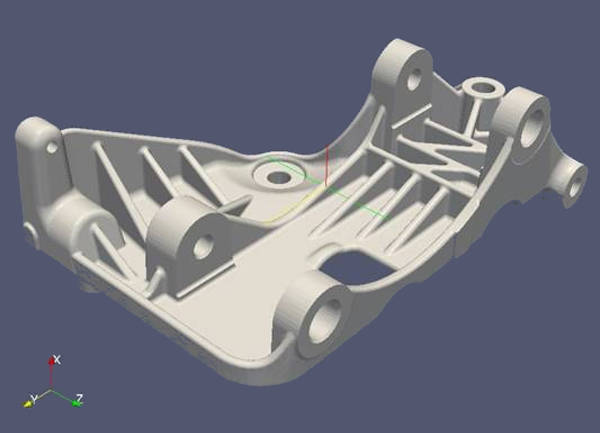

- Part Information

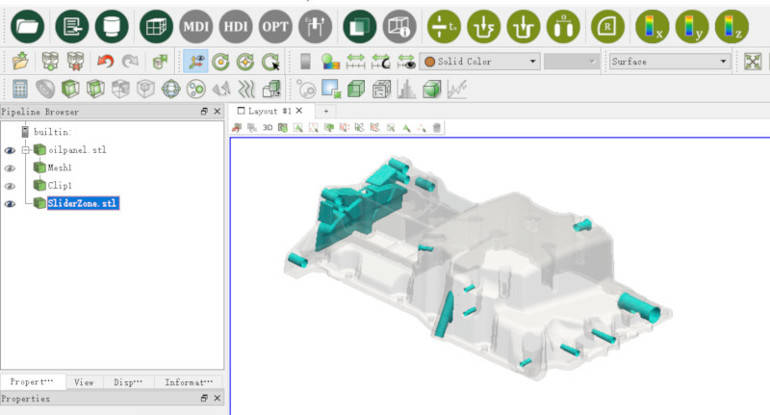

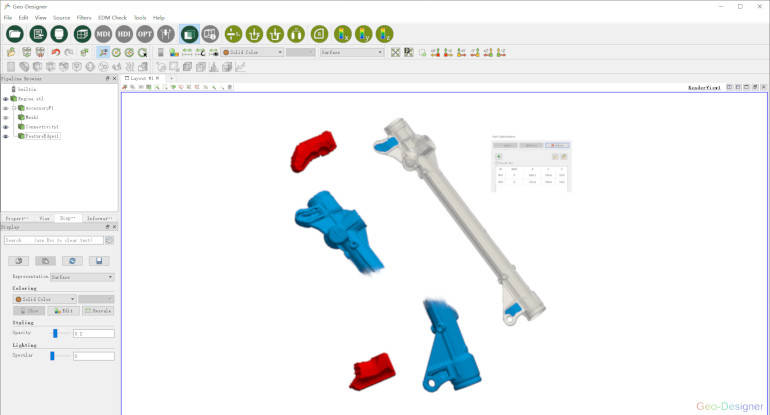

- Slider / Core Checking

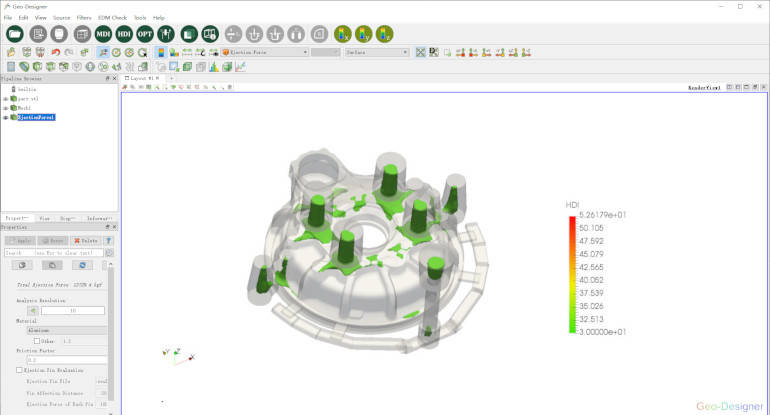

- Ejection Force

- Core Extraction

- Part Optimization

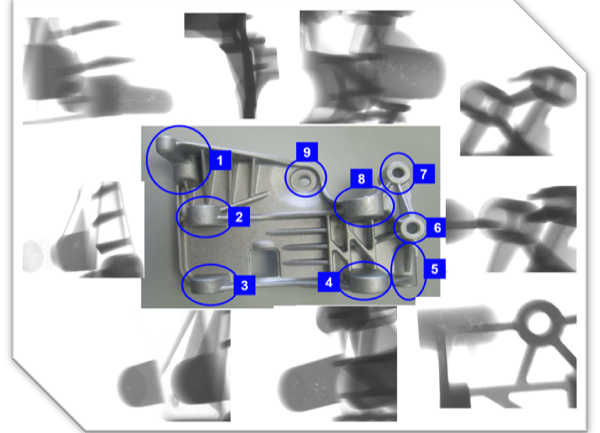

Hot spots in mass distribution index (MDI) of part

Heat distribution index (HDI) of part with gating & riser

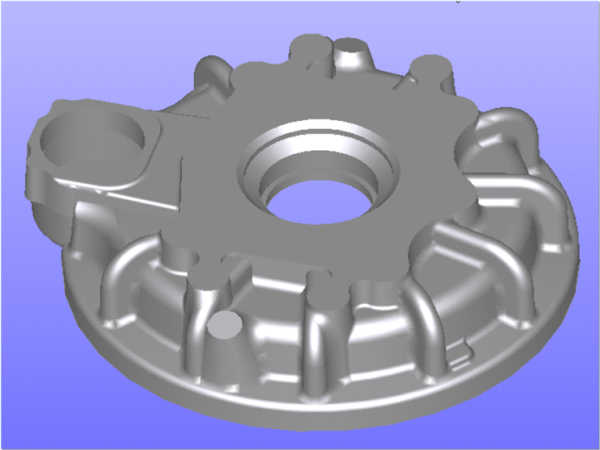

Part information

Ejection force

Core extraction

Part optimization

Benefits

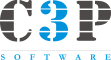

Find Hot Spots! In 3 Clicks, 3 Minutes!

Start from 3D Part

Import 3D file to Geo-Designer directly, support STL, IGES, STEP and BREP file format

3 Clicks for a study

Easy, express and powerful tool for DFM analysis, 3 clicks only for a study

3 Minutes to get result

The results include MDI, HDI(hot spots), ejection force, part information and more...

Validate by X-Ray

The good agreement between the DFM result and real X-Ray result.

Riser & Feeder Design for Gravity Casting

Start from 3D Part

Import 3D file to Geo-Designer directly, support STL, IGES, STEP and BREP file format

MDI / HDI Analysis

The MDI/HDI results give clear information of the thick region of the casting, where the riser or feeder should be placed

Riser / Feeder design

With build in design capability for simple riser/feeder, rib and chill design

Check the designed riser & feeder

The designed components could be evaluated online and mesh base Boolean operation is also supportedPricing

Flexible price plan for your business (Currency in USD)

Monthly

$299 / month

- Unlimited runs

- One month license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Half yearly

$1,794

$1,649 / 6 months

- Unlimited runs

- Six months license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Yearly

$3,588

$2,999 / year

- Unlimited runs

- One year license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Success Stories

How about others to use Geo-Designer

Lorenzo Ciavolella

Technical Department Manager (MennaCasting - Italy)

Our in-house casting simulation software takes hours to calculate even a simplified solidification simulation. With Geo-Designer we can sit side by side with the customer's designer, check the MDI of the part in a minute, and ask to the designer to make the necessary design changes in real time.

COMPANY

As a key supplier of high aesthetic quality finished components, MennaCasting manufactures a variety of spotlight supports, engine and gear covers, structural frames, and accessories that are used in the automotive, motorcycle and consumer industry. The casting process is HPDC withmagnesium alloy, some of MennaCasting customers are Ducati, Technogym and Guzzini.

CHALLENGE

They needed a tool to improve the communication and theco-design phase with the customers, to prevent to receive casting parts approved and ready for production with potential problems related to thecasting process. The idea was to support the customer to develop casting parts free of defects starting from the first design stage, to avoid problems in production, reduce costs, and control quality.

BENEFITS

- Cut development cycles by 25 percent.

- Moved from concept to production mold in two weeks.

- Reduced time waste for customer part review by over 75 percent.

- Improved overall casting quality and reduction of scraps.

ErdemAYDOĞMUŞ

Project & EngineeringManager (Çelikel - Turkey)

Geo-Designer help us to detect shrinkage porosity, best gates positions and evaluate cooling channels locations in a matter of minutes. Now our preliminary quotations are reliable and really close to the real final cost of the product.

COMPANY

Specialized in responding with highest quality standards, to all the expectations of automotive and white goods industries, at all levels, from the engineering solutions to the end products for about half century, ÇELİKEL Aluminum continuously improves its approach to a sustainable world and future through its teamwork to create collective values and innovative targets.

CHALLENGE

The main problem of ÇELİKEL Aluminum was to answer to all the quotation requests that where coming from the customers each day. The in-house casting simulation software, because of the long calculation time needed, it is used only to validate the mold design of already approved orders. Without a correct evaluation of the hot spots and of the position of the necessary cooling channels, the quotation was prone to errors.

BENEFITS

- Quotation errors reduced by 95 percent.

- Fast evaluation of hot spots, gate position and cooling channels.

- Quotation time reduced from 2 days to few hours.

- Mold development time reduced by 30 percent.

Nicola Giardinelli

Technical Department Manager (Jodovit - Italy)

Geo-Designer let us evaluate the part modulus and the shrinkage porosity areas of the casting part in a very reliable and fast way. Validate the design after adding risers, feeders, sleeves and chillers can be done in few minutes, so we can check many design options in few hours.

COMPANY

Jodovit is since 1958 manufacturer of chemical auxiliares for metal treatment. The Jodovit's activities are all oriented to the continuos development of products and services to increase the quality and efficiency of productive processes for metal treatment. The close collaboration with the customers and an efficient technical assistance on the international markets characterize our company.

CHALLENGE

One of the main Jodovit products are the insulating and exothermic sleeves. The challenge was to support and guide the customers in the right choice of the product to compensate the shrinkage porosity of the casting. The customer design must be validated before going in production, to be sure to end up with a casting free of defects. The high number of designs to check each day requires a fast and flexible simulation tool.

BENEFITS

- Very fast evaluation of hot spots that can cause shrinkage porosity.

- Check of three or four alternative design solutions in few hours.

- Accurate simulation of both insulating and exothermic sleeves.

- Improved relationship with customers thanks to the service provided.

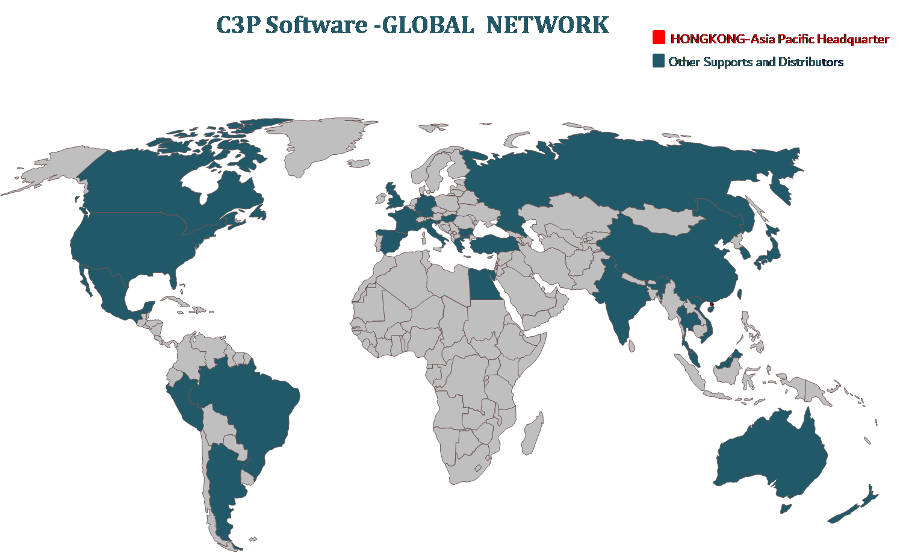

C3P SOFTWARE

Complete solution for casting, stamping and welding industry

C3P Engineering Software International has been founded in 2006 and providing the professional design & analysis solution for the manufacturing industry. Our main products are "Cast-Designer", "Cast-Designer Weld", "Geo-Designer", "AI-FORM" and "SavingCAST", which were already captured the Global market. We have sold our products in more than 28 countries and those countries have our distributors. We are not famous by our Company name but by our products. The Software specially focuses on the virtual manufacturing field to provide end-to-end solution for metal casting, sheet metal forming, weld and assembly. Our solution built in the Design for Manufacturing, Design Capability, Advance Front Simulation, the last CAE technology, Automatic Optimization and Final Performance Validation to a whole package; to consider the Multi-Physics, Multi-Scale and Real Material. As a pioneer of numerical simulation solution provider, C3P Software provides the industry and the manufacturing business with comprehensive solutions and engineering services on a global basis to meet their expectation in high quality, on-schedule delivery within cost target. Our business scope covers software development, professional engineering service, and application software integration.