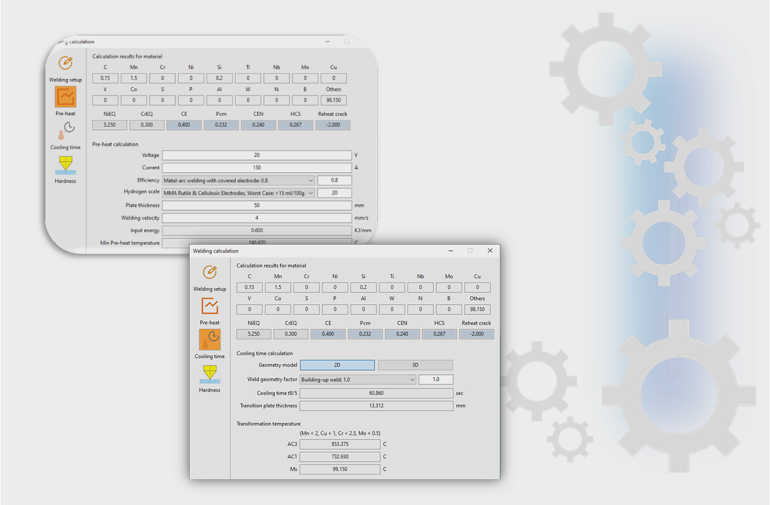

Analysis the Material Weldability

- To find some metals or thermoplastics which can be easier to weld

- A material's weldability is used to determine the welding process and to compare the final weld quality to other materials

- Improving quality and competitiveness of your company

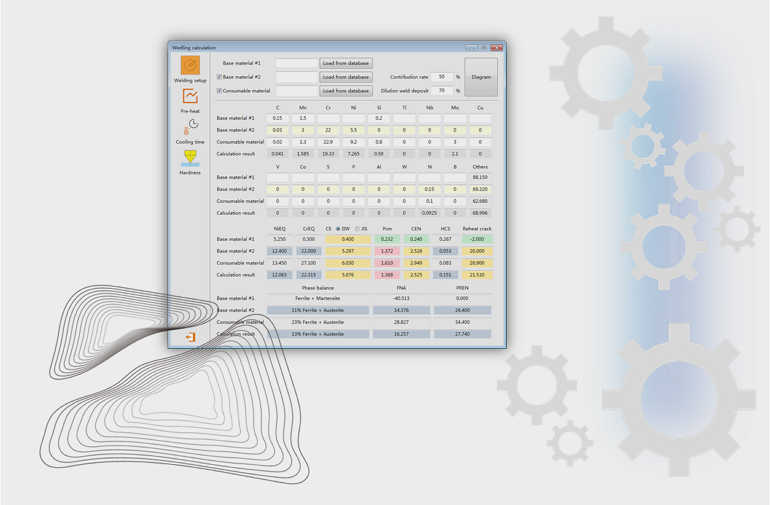

Calculate Many Useful Results

- CE, NiEQ, CrEQ

- PCM, CEN, HCS, Reheat crack

- Phase balance, FNA

- Cooling time t8/5

- Preheat temperature

- AC1, AC3, MS

- HAZ hardness, tensile strength etc.

- Calculation the required filler metal quantities

Key Features

- Support user database

- Supports the planning of welding tasks

- Supports the optimization of welding tasks

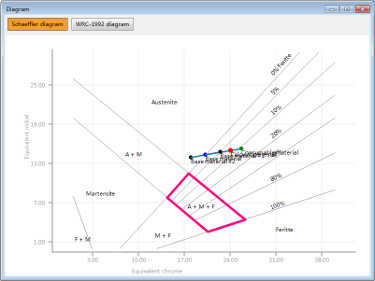

- Rich result analysis

- Multi-language support

Support user database

supports the planning of welding tasks

Supports the optimization of welding tasks

Rich result analysis

Multi-language support

Benefits

Customer database

Easy to learn, easy to use

Enhance industry competitiveness

Optimize the welding tasks and conditions

Weldability control in early stage

Detail process calculation

Compare the final weld quality

Very detail results analysis

Pricing

Flexible price plan for your business (Currency in USD)

Monthly

$59 / month

- One month license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Half yearly

$354

$319 / 6 months

- Six months license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Yearly

$708

$599 / year

- One year license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Success Stories

How about others to use Welding Calculator

Solution

We face many challenges, including producing high-quality welding products while maintaining low costs. Implementing and providing the optimal software solution under various controls such as material selection, cooling time, preheating temperature and required filler metal amount will bring many benefits and achieve competitive success.

BACKGROUND

Many metals and thermoplastics can be welded, but some materials are easier to weld than others. However, between different materials, how to choose the material of the intermediate layer to make it easier to weld, there are big technical problems. Such as material selection, cooling time, preheating temperature and the amount of filler metal required. Therefore, weldability analysis is largely used to determine the welding process and compare the final welding quality with other materials.

CHALLENGE

There are many internal factors that affect weldability, so these factors pose a huge challenge to technical engineers in the manufacturing industry to improve product quality and zero-defect welding processes. If you simply deal with it through trial and error, it will not only be inefficient, but also waste of resources, and you will not be able to obtain high-quality products.

C3P SOFTWARE

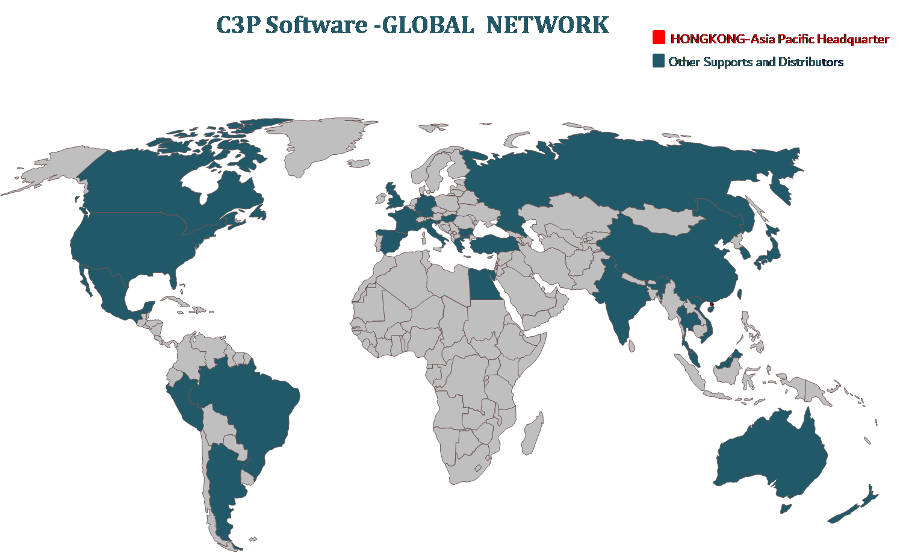

Complete solution for casting, stamping and welding industry

C3P Engineering Software International has been founded in 2006 and providing the professional design & analysis solution for the manufacturing industry. Our main products are "Cast-Designer", "Cast-Designer Weld", "Geo-Designer", "AI-FORM" and "SavingCAST", which were already captured the Global market. We have sold our products in more than 28 countries and those countries have our distributors. We are not famous by our Company name but by our products. The Software specially focuses on the virtual manufacturing field to provide end-to-end solution for metal casting, sheet metal forming, weld and assembly. Our solution built in the Design for Manufacturing, Design Capability, Advance Front Simulation, the last CAE technology, Automatic Optimization and Final Performance Validation to a whole package; to consider the Multi-Physics, Multi-Scale and Real Material. As a pioneer of numerical simulation solution provider, C3P Software provides the industry and the manufacturing business with comprehensive solutions and engineering services on a global basis to meet their expectation in high quality, on-schedule delivery within cost target. Our business scope covers software development, professional engineering service, and application software integration.