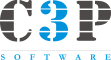

Saving Money for Casting Raw Material

- Helps reducing the cost of charges up to 25%

- Improving quality and competitiveness of your company

- Fast response capability to changes

Saving Time for Material Charging

- Simple operation

- Immediately response

- Accurate charging

- Optimizing resources

- Build-in the last AI technology

- Improving quality

- Achieving operational excellence

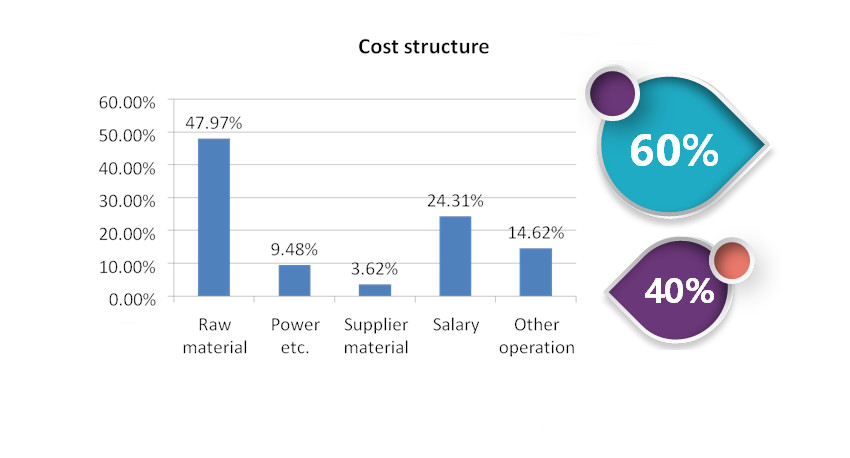

Calculation of the Metal Charge for Black and Nonferrous Metals

- Suitable for all casting material

- Suitable for all casting process

- Unlimited elements of the target alloy

- Unlimited raw materials

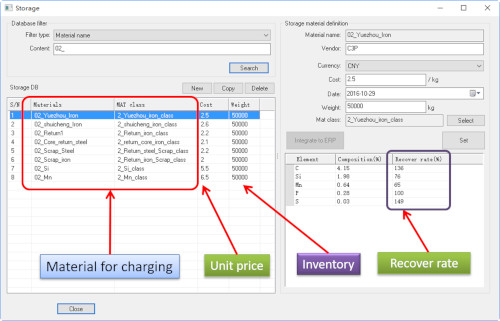

- Easy to integrate with the ERP system

Key Features

SavingCAST strictly follows the chemical composition range required by the alloy grade of the casting, and strives for low cost under the premise of fully ensuring the quality of the casting.

- Reduce raw material cost directly

- Build-in the last AI technology

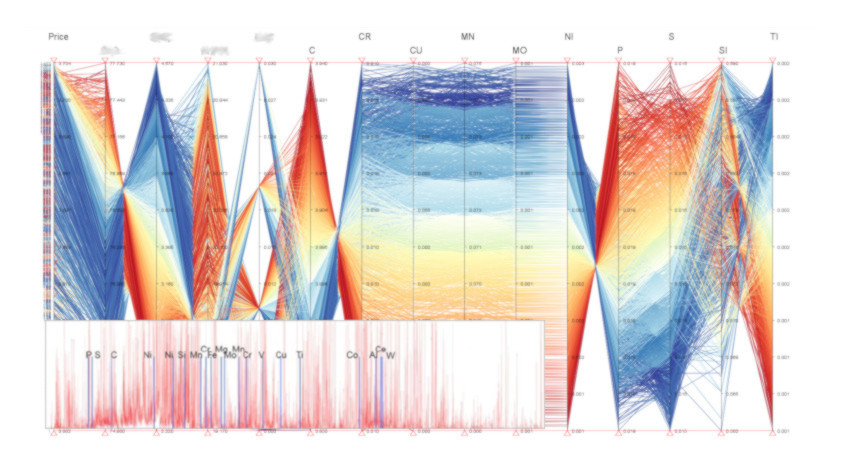

- Rich tools for result analysis

- Immediately response for workshop result

Benefits

Easy, powerful and accurate tools for alloy charging

Easy to use

Less than half hour to learn the analysis tools

Save material cost

Optimize the element composition based on the minimum cost

Accurate charging

Consider the element loss and increasing during the charging process

Improve quality

Build in calculator to predict the final casting part mechanical properties to guide the alloy charging

User’s database

The system supports user’s database for casting alloy material, raw material and storage database

Support user’s formula

The user can define special formula for the target optimization criteria

Professional report

Calculation result report could be transferred to MS Excel and PDf format and used for workshop directly

Enhance competitiveness

The charging cost could be reduced, alloy chemical composition accurate could be increased and engineer knowledge could be enhanced alsoPricing

Flexible price plan for your business (Currency in USD)

Monthly

$399 / month

- Unlimited runs

- One month license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Half yearly

$2,394

$2,199 / 6 months

- Unlimited runs

- Six months license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Yearly

$4,788

$3,999 / year

- Unlimited runs

- One year license period

- Free maintenance and upgrade

- Online support

- Email support

- Offline to use software

Success Stories

How about others to use SavingCAST

Mr.Ho

Manufacturing Manager of CMP group

'SavingCAST help us to find the best material charging plan, it is much advance than the tradition Excel table and Engineer experience. With the support of SavingCAST, we can obtain the ideal alloy composition in one time.'

COMPANY

China metal Products (CMP) Co., Ltd was founded in 1972. Started as an iron casting business with a philosophy of diligence, integrity, and sustainability as its core. Today, the CMP Group employs a workforce up more than 4,500 and controls over NT four billion in capital.

CHALLENGE

How to reduce the charging process time and iterations, as well as increase the element composition accurate is the Key of the company.

BENEFITS

- Material cost reduce 12.3% compared the original charging plan.

- 100% achieve the customer element composition requirement.

- Material mechanical properties increase 2%.

- Immediately responsible of the workshop.

Manager Wu

Casting department

'The benefit of SavingCAST to us was very clear, our material cost has cut around 190 RMB per ton or around 2 million RMB per year for us. This software tools is very easy wo use and it can integrate the online system to control the alloy quality online!'

COMPANY

North casting industry (NCI) Co., Ltd is a professional manufacturer of steel casting. Which was established in 1989. The company covers an area of 1776,000 square meters with over 1600 employees. Products are widely used in construction machinery, engineering equipment, mining machinery, trucks, shipbuilding and other industrial fields.

CHALLENGE

Due to the application and big size part, the mechanical properties of the casting alloy is very important. And the element composition is required very accurate. The existed charging plan always had some small different duo to the different material source. The hish material charging cost also impact the company’s profit.

BENEFITS

- 100% achieve the element composition requirement.

- Save 8% material cost (or RMD 189/ton) compared to the original charging plan.

- Charging lead time reduce 70%.

- Increase the ready material rate from 38% to 46%.

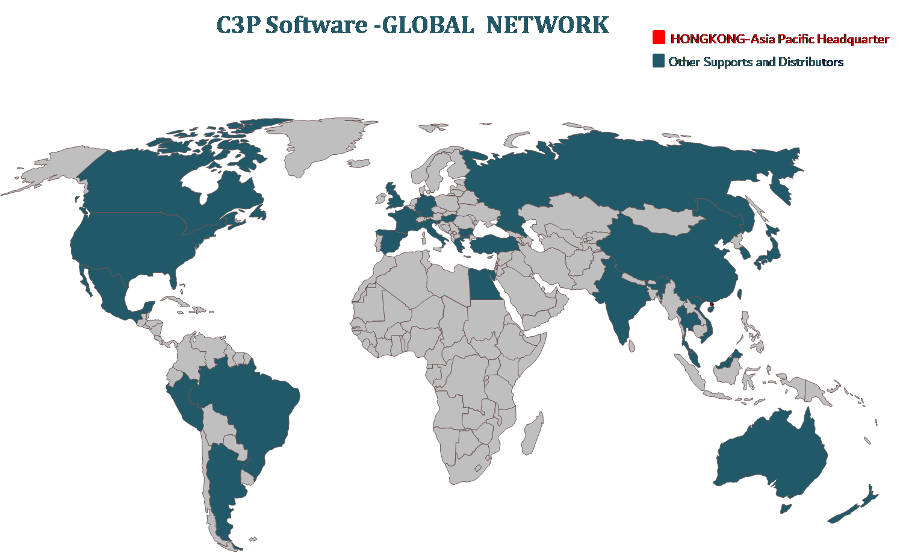

C3P SOFTWARE

Complete solution for casting, stamping and welding industry

C3P Engineering Software International has been founded in 2006 and providing the professional design & analysis solution for the manufacturing industry. Our main products are "Cast-Designer", "Cast-Designer Weld", "Geo-Designer", "AI-FORM" and "SavingCAST", which were already captured the Global market. We have sold our products in more than 28 countries and those countries have our distributors. We are not famous by our Company name but by our products. The Software specially focuses on the virtual manufacturing field to provide end-to-end solution for metal casting, sheet metal forming, weld and assembly. Our solution built in the Design for Manufacturing, Design Capability, Advance Front Simulation, the last CAE technology, Automatic Optimization and Final Performance Validation to a whole package; to consider the Multi-Physics, Multi-Scale and Real Material. As a pioneer of numerical simulation solution provider, C3P Software provides the industry and the manufacturing business with comprehensive solutions and engineering services on a global basis to meet their expectation in high quality, on-schedule delivery within cost target. Our business scope covers software development, professional engineering service, and application software integration.